ZCC Tungsten Carbide Milling Insets SEKR1203 Cutter For Milling Factory Wholesale

Basic Information

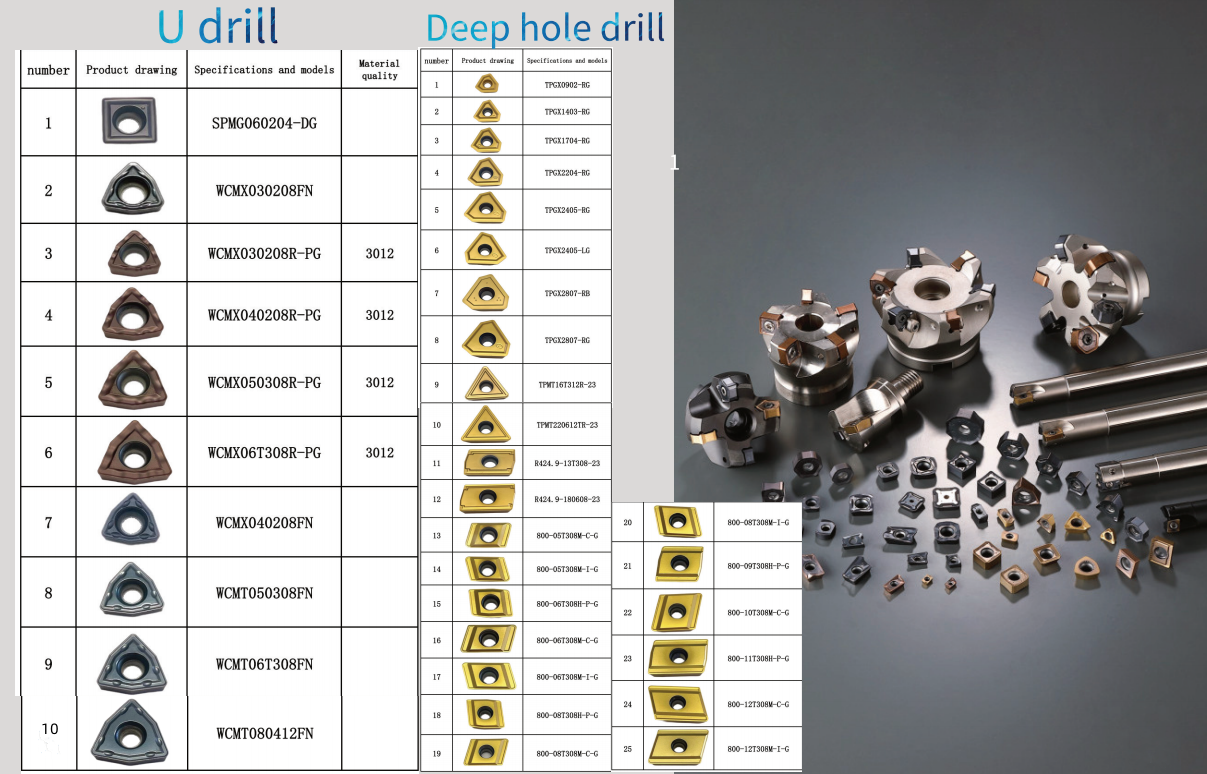

1.Tungsten carbide zvishandiso zveKushandura kuisa

CNMG/TNMG/WNMG/DNMG/SNMG/VNMG/CCMT/DCMT/SCMT/TCMT/VBMT/KNUX

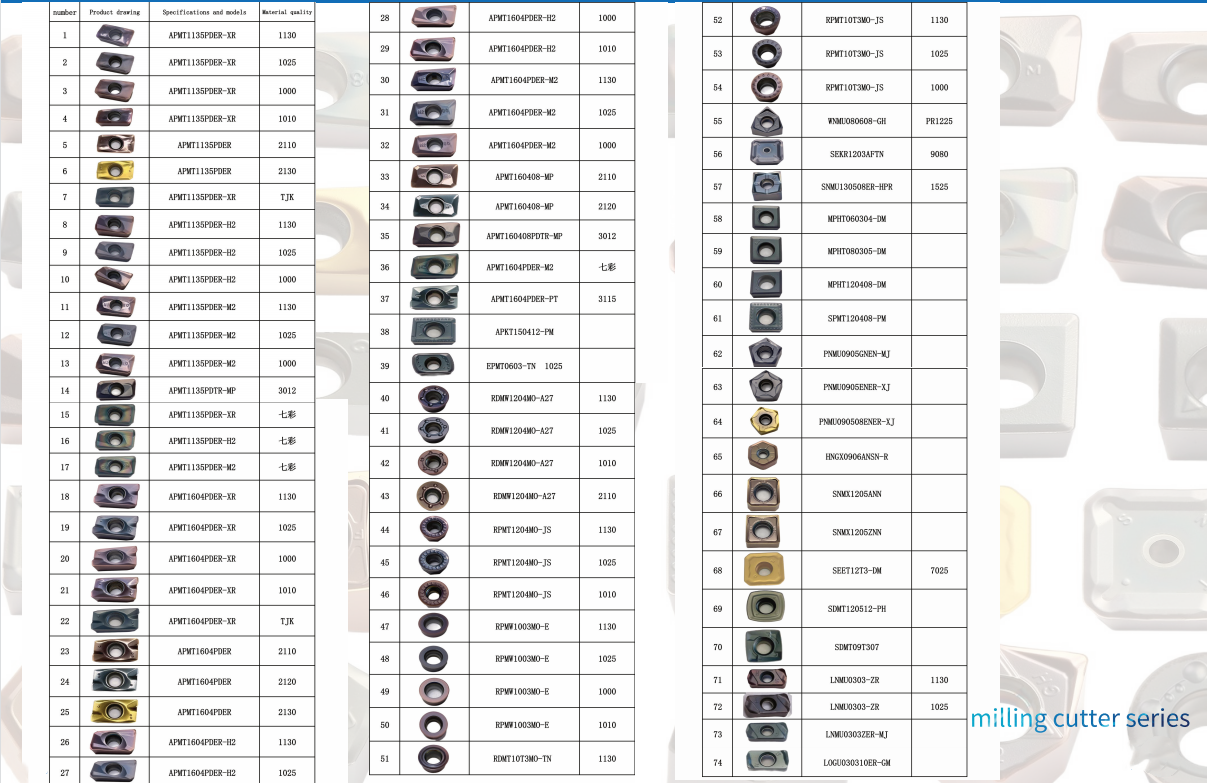

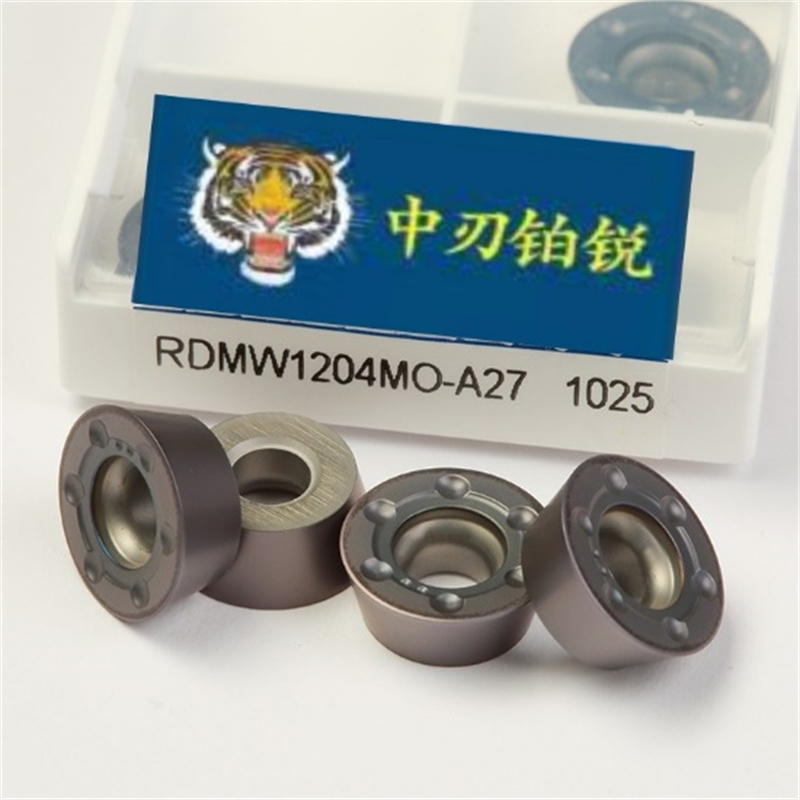

2.Tungsten carbide zvishandiso zvekugadzira milling

APKT/APMT/RPKW/RDKW/RCMT/SPKN/TPKN

3.Tungsten carbide zvishandiso zveAluminium inoisa kucheka

CCGT/DCGX/SCGX/TCGX/VCGX

4.PCD &PCBN Tungsten carbide maturusi ekutendeutsa kuisa

CNGA/DNGA/SNGA/TNGA/VNGA/CCGW/DCGW/TCGW/VBGW

Application

Main Application:Yekugadzirisa kabhoni simbi, simbi yakakandwa, simbi isina tsvina

Indasitiri yekushandisa:

CNC kutendeuka uye kugaya tungsten carbide maturusi maturusi maturusi anoiswa anoshandiswa zvakanyanya mu: Automotive kugadzira indasitiri, Mold kugadzira indasitiri, Aviation indasitiri, Defence indasitiri, Heavy processing industry uye mamwe akawanda munda.

isu tinogona kugadzira akasiyana marudzi tungsten carbide yekucheka maturusi anoisa zvinoenderana neakasiyana akadhirowa akadhirowa.

isu tinogona kupa iyo yakazara tsigiro mhinduro kune machining munda.

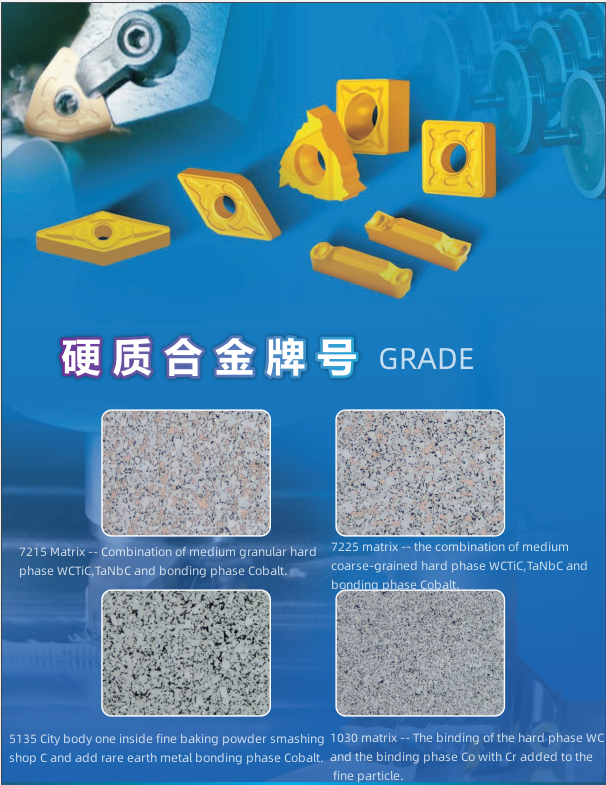

Material Giredhi Nhanganyaya

Nhanganyaya yekushandura zvinhu sumo:

7215 ine simba repamusoro uye kuoma kweyakanyanya toxicity resistance matrix, yakasanganiswa neMT-TICN, AL2O3,TIN yakanakisa musanganiswa wekupotera, uyezve kuburikidza nepamusoro pekuvhara mushure mekurapa kubvisa kushushikana kwemukati kweblade layer, yakakodzera kupedzisa simbi.

7125 kumucheto kuchengetedzeka kwesimba rakakwirira, kusimba kwepamusoro matrix yakasanganiswa neMT-TICN uye superfriction AL203 yekupfekedza maitiro, uyezve kuburikidza nepamusoro pekuvhara mushure mekurapa maitiro ekubvisa kushushikana kwemukati kwejasi, yakakodzera kune yakajairwa simbi rough processing, semi-kupedza uye. chikamu che workpiece roughness zvinodiwa haisi yepamusoro kupedzisa.

4025 yakakwira corrosion kuramba, uye kuburikidza neimwe yekumanikidza sintering process yeyakanyanya simba matrix uye MT-TICN uye super gobvu AL2O3 coating yakanakisa musanganiswa, ine yepamberi yekupotera mushure mekurapa tekinoroji kuti iwane yakapfava yekuvhara pamusoro, inokodzera hutsinye machining, semi-kupedza. uye kupera kwesimbi yakaumbwa.

1030 zviyo zvakanaka, yakanakisa deformation kuramba uye kuburikidza nekumanikidza sintering maitiro kuti uwane yekupedzisira-yakakwirira simba uye kupfeka kuramba matrix, ine nano PVD coating process, uyezve kuburikidza nepamusoro pekuvhara post-kurapwa kuti uwane yakatsetseka yekuputira nzvimbo, yakakodzera yakajairwa simbi kupedzisa, simbi yakadzima, chromium plated simbi uye Stainless simbi semi-kupedza uye kupedza.

1120 Ultra-yakanaka zviyo, yakanakisa deformation kuramba, uye kuburikidza nekumanikidza sintering maitiro kuti uwane yakakwira simba uye kupfeka kusaga matrix, ine nano SI ine PVD coating process, mushure mepamberi yekupotera mushure mekurapa kuti uwane yakatsetseka yekuputira pamusoro.Inokodzera grooving uye kucheka kwesimbi yakajairika, simbi yakaoma uye simbi yakakandwa.

Nhanganyaya yekugaya uye kuchera zvinhu

1030 NC-TIALN coating yakasanganiswa neakasimba uye ductile matrix yezvimedu zvakanaka inokodzera kugaya uye semi-kupedzwa kwemarudzi ese ezvishandiso zvakagadziriswa.Grooving, kucheka uye kuchera kwehafu aperture.

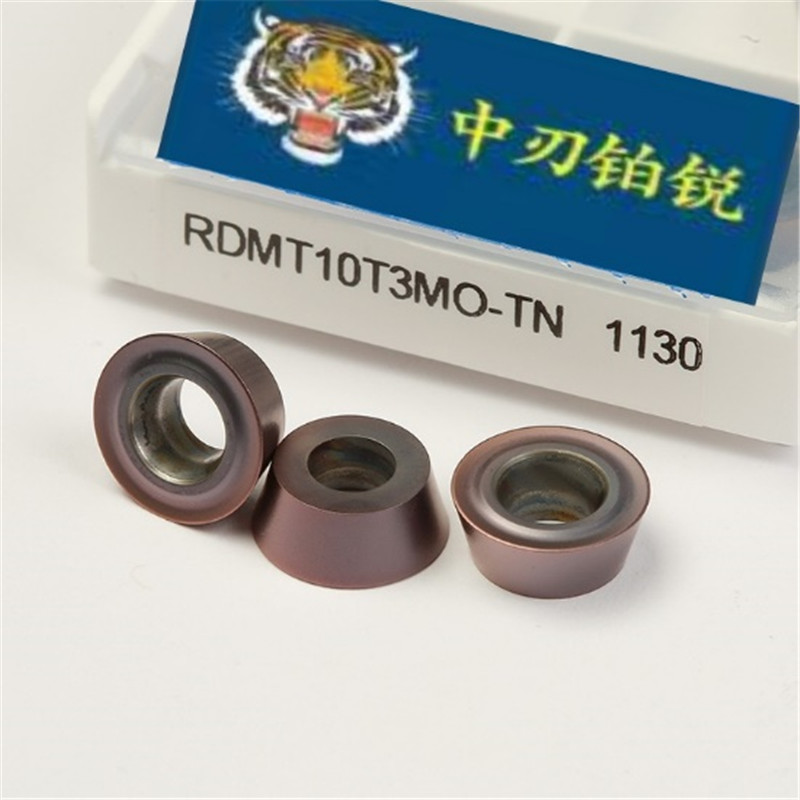

1130 NC-TIALN coating ine SI inosanganiswa neakanaka zvimedu uye kusimba kwakanaka kweakaomeswa alloy matrix, akakodzera simbi isina tsvina, simbi yakakandwa chikamu uye semi-yekupedzisira kugadzirisa, kuwana musanganiswa wakakwana wekuchengetedza uye kupfeka kuramba.

5035 yakawedzera kupfeka uye yakakwira tembiricha yekudzivirira zvinhu zveCVD coating, kuomarara kwakakwira uye yakanakisa kupisa tembiricha kuti ipe dziviriro inoshanda kune yekucheka kumucheto, yakakosha yekupfekedza tekinoroji yekurapa, coating uye matrix zvakanyanya kusimba, yakakodzera kune yakanyanya kupisa alloy, titanium alloy zvinhu kunyatsoita. kugadzira milling.

5135 NC-TIALN coating ine SI yakasanganiswa ne carbide matrix ine yakanakisa kukanganisa kusimba, yakakodzera kune simbi simbi, Stainless simbi, grooving, kucheka kwakadzika kucheka, kukurumidza kudyisa kugadzirisa uye yakakura aperture drilling processing.

Zvigadzirwa Zvinotsanangurwa

Coating Display

Zvitupa

Zvishandiso zvekugadzira

QC Equipments

Zvakanakira

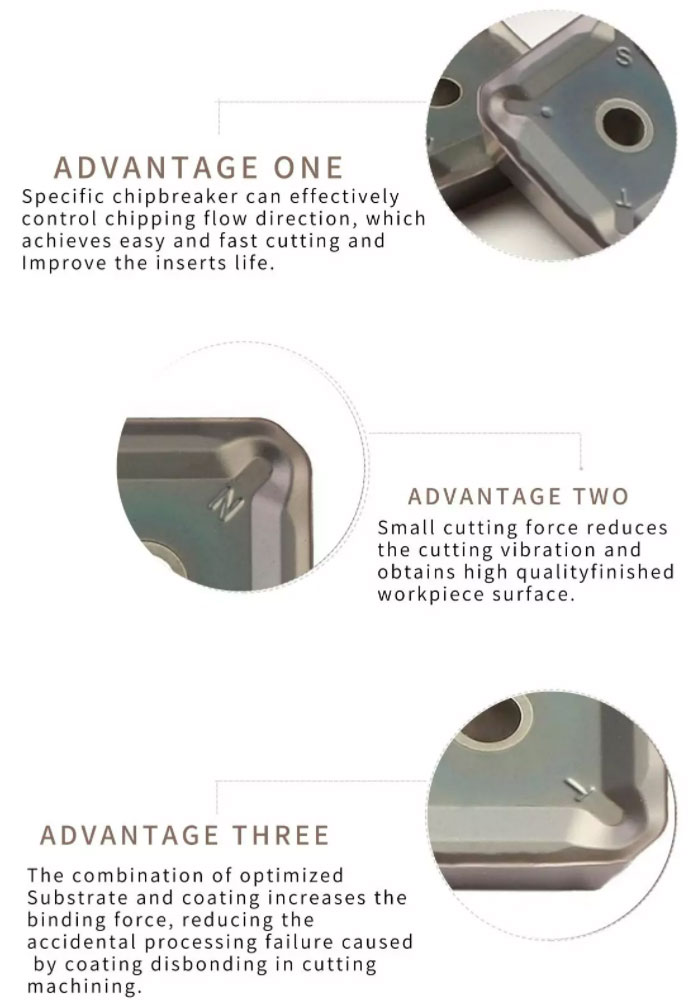

1.Groove dhizaini, iyo yekucheka inodzora inotsvedzerera, zvinobudirira kuderedza kucheka kushorwa, kuve nechokwadi chehupenyu hurefu hwekushandisa;

2.High quality zvinhu;

3.Fine kugaya nzira, isu kushandisa kunze kwenyika kugadzira muchina, otomatiki peripheral kugaya muitiro, yepamusorosoro nemazvo, kunopinza kupfeka.

Masevhisi Edu:

Zvinopfuura 2000 zvigadzirwa zviripo.Assembly mutsara kugadzirwa, yakakwirira mwero uye zvakasimba zvinodiwa.

OEM Sevhisi Inopihwa.

Customized Tools Inopihwa.

Yemahara laser yekumaka pane zvishandiso uye mabhokisi Inopihwa.

Kurumidza kuendesa nguva uye Yakanaka Yekufambisa.Isu tine mutero pamutengo wekutumira kubva kumakambani edu ekutumira, akadai seFedEx, DHL, TNT, UPS nezvimwe.