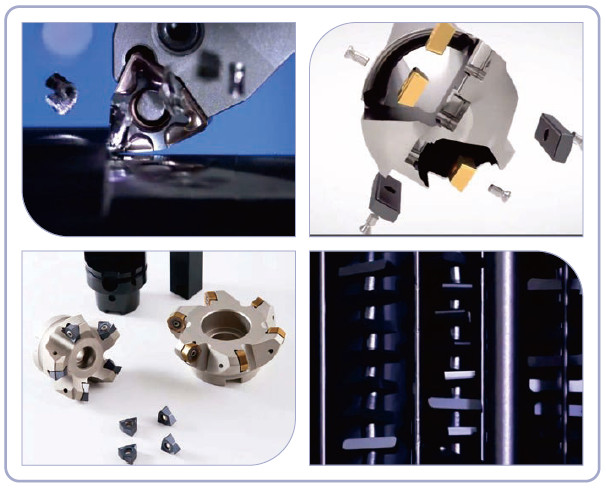

Iyo nzira yekucheka inoverengera inosvika 90% yebasa rekugadzira machining.Chishandiso ndicho "zino" remuchina wemuchina weindasitiri, unobata zvakananga padanho rekugadzirisa indasitiri yekugadzira.Kucheka kunoreva kuchekwa kwezvinhu zvakawandisa kubva pachiso chebasa, kuve nechokwadi chekuti workpiece geometry, dimensional kurongeka, kunaka kwepamusoro uye zvimwe zvikamu zvezvinodiwa zvekugadzira nzira yekugadzira, inoverengera inosvika 90% yebasa rese remachining.Kucheka kunowanzo kuwanikwa nekucheka maturusi emuchina, uye chishandiso ndicho chinhu chakakosha chinodyiwa, se "mazino" emaindasitiri emuchina maturusi, hunhu hwayo hunokanganisa zvakananga kugadzirwa kwemichina yekugadzira tekinoroji level, kugona kwekugadzira uye kunaka kwechigadzirwa.Kucheka maturusi kumusoro kwemvura kune vatengesi vezvigadzirwa, kudzika kunoshandiswa mumaindasitiri makuru ekugadzira.Tora iyo inonyanya kukosha carbide chishandiso semuenzaniso, maererano neyakagadziriswa zvinhu zvinogona kukamurwa kuita: simbi, simbi isina tsvina, simbi yakakandwa, isina-ferrous simbi, kupisa-resistant alloy, yakaoma simbi, etc. Kumusoro kune inofananidzwa mbishi zvinhu ( tungsten carbide, cobalt poda, tantalum niobium solid solution, etc.) vagadziri, iyo yakadzika pasi application ndima yakatarisana muindasitiri yekugadzira, inonyanya kushandiswa mumotokari nemudhudhudhu, maturusi emuchina, general muchina, mold, mainjiniya nemimwe minda, aerospace, mauto, muchina wekurapa uye mamwe minda zvakare inopa yakakura tekinoroji application uye shanduko nzvimbo yecarbide maturusi.

Ndeapi maitiro emidziyo yekucheka carbide?

1.kuoma kwepamusoro: Carbide tool inogadzirwa ne carbide nehupamhi hwekuoma uye nzvimbo yakanyunguduka (inozivikanwa sechikamu chakaoma) uye simbi binder (inozivikanwa sechikamu chinosunga) nehupfu metallurgy nzira, kuoma kwayo ndeye 89 ~ 93HRA, yakakwirira kudarika simbi inomhanya. , pa5400C, kuoma kuchiri kukwanisa kusvika 82 ~ 87HRA, uye high speed simbi mukamuri tembiricha kuoma (83 ~ 86HRA) zvakafanana.

2. Kupeta kusimba uye kusimba: kupeta simba kweyakajairwa yakaoma alloy iri mukati me900 ~ 1500MPa.Iyo yakakwirira yemukati yesimbi inosunga chikamu, iyo inokwirisa iyo yekukombama simba.Kana iyo binder yemukati yakafanana, YG(WC-Co).Simba reiyo alloy rakakwira kupfuura YT (WC-Tic-Co) alloy, uye simba rinodzikira nekuwedzera kweTiC zvemukati.Hard alloy imhando ye brittle zvinhu, kusimba kwayo kusimba pakamuri tembiricha inongova 1/30 ~ 1/8 yeHSS.

3. Kuramba kwakanaka kupfeka.Iyo yekucheka yekumhanya yecarbide chishandiso ndeye 4 ~ 7 nguva yakakwira kupfuura iyo yekumhanyisa simbi, uye hupenyu hwekushandisa hwakareba 5 ~ 80 nguva.Kugadzira mold, maturusi ekuyeresa, hupenyu kupfuura alloy tool simbi 20 ~ 150 times yakakwirira.Inogona kucheka 50HRC kana zvinhu zvakaoma kudaro.

Nguva yekutumira: Zvita-29-2022